WHAT IS nZVI?

nanoscale Zero-Valent Iron

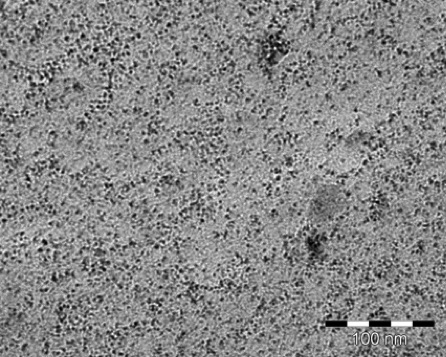

In-situ chemical reduction is performed using an extremely tiny, nanoscale suspension of elemental iron (Fe0 – zero-valent); this is the origin of the abbreviated English (international) name of the process: nZVI (nanoscale Zero-Valent Iron). The nanoscale range of particles (1-5 nm) is demonstrated by transmission electron microscopy images and the particle size distribution (see below).

Due to the nano-size of particles, the elemental iron particles move freely, practically together with water molecules in the pore space allowing for in-situ delivery.

PARTICLE SIZE DISTRIBUTION

nZVI PRODUCTION

nZVI is produced from the reduction of inorganic Fe compounds

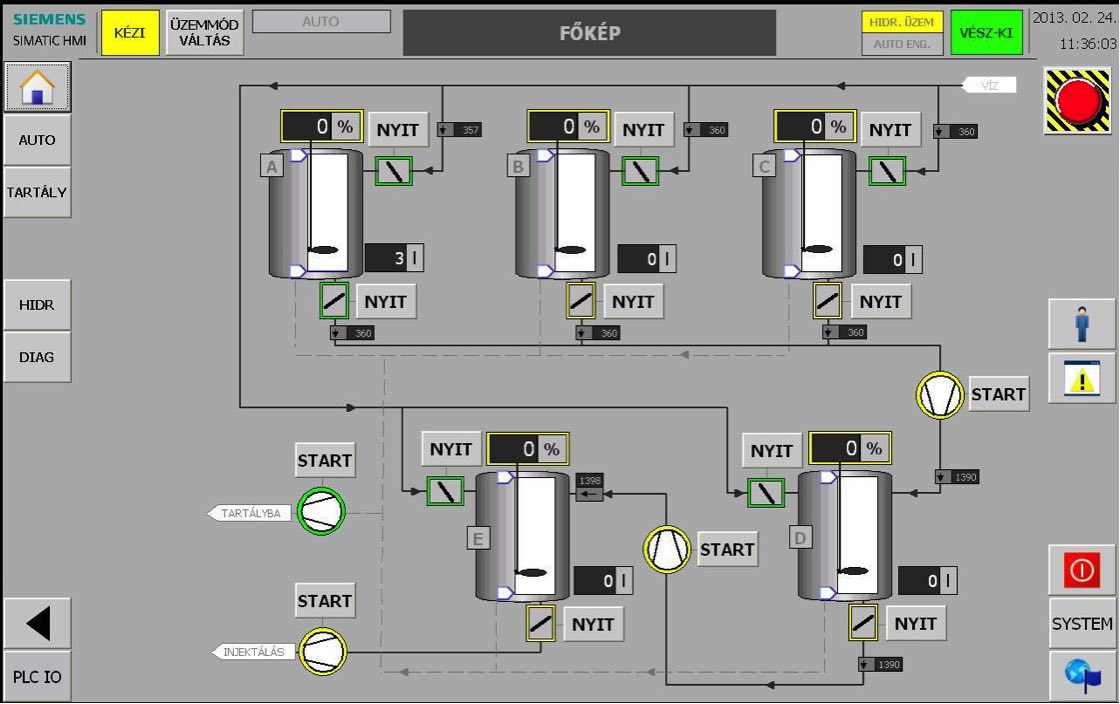

Being a powerful chemical reaction and since the compounds to be used need to be dissolved from crystal sate on site, nZVI production is performed in a mobile production equipment consisted of stainless pressure reaction vessels, hydraulic (non-sparking) mixing engines, and electronically regulated decanting and supply system.

The production equipment is mobile, i.e. mounted on a heavy trailer, equipped with its own energy supply (three-phase generator) if required.

There is a minimal volume of hydrogen gas formation during production therefore, the reaction is conducted under nitrogen cushion in the tanks. Tanks are equipped with a safety relief system.